Course# 501

Aging Aircraft Course (Sustainment Course)

When a student completes this course she/he should be able to:

- understand what factors cause aircraft to age

- learn about Multiple Site Damage and Widespread Fatigue Damage and how to postpone them

- have a basic understanding of aircraft loads and aerodynamics and how they contribute to aging

- recognize up to a dozen different types of corrosion that can afflict an aircraft and how to minimize their occurrences

- explain what Limit of Validity is for aging aircraft

- have a good working knowledge of aging aircraft wiring issues and EWIS

- show a solid grasp of various factors that contribute to aircraft fatigue crack initiation and growth

- be familiar with best practices to mitigate aging issues in aircraft

Who should take this training:

Managers / Engineers / Materials Scientists / Inspectors / DERs in:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From Industries including but not limited to:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Syllabus

Aging Aircraft Course / Sustainment Course

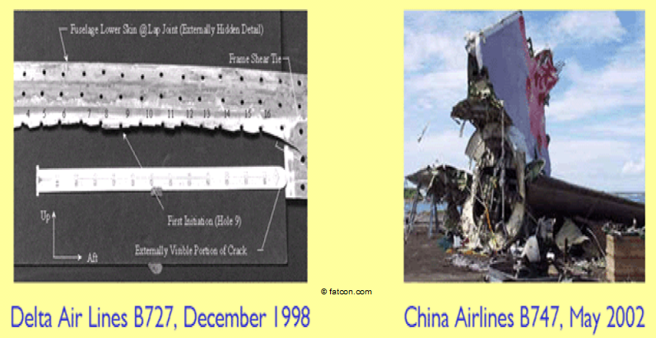

- Things that ‘age’ an AircraftFatigue Crack Initiation & Propagation, Corrosion, Foreign Damage, Synergistic Failure Modes, Susceptibility of High Strength Materials

- Convertible in the Sky!!

Deadly Corrosion + Fatigue Combination, Short-Hop Flights — Effect of Spectrum on Aging, Inspections, Important Lesson on Fail-Safe. - Fail Safe, Safe Life & Damage Tolerance

Structural Illustrations, Safety Factors, Miner’s Myth (Miner’s Rule), Fracture Mechanics Fundamentals, Crack Growth Example, Practical Data, Residual Strength - Airworthiness Assurance Task Force Findings

Human Factors, NDT Technology, Inspector/mechanic Training, Maintenance Communications, Fatigue Testing - Multiple Site Damage– Widespread Fatigue Damage

- How Aging affects Fail-Safety

Case Study: Boeing 747 Flap Track Assembly Stress Corrosion - Aircraft Certification — Transport and Commuter

- Protection against Wear, Spalling, Galling…

- Fretting Fatigue

Case Study: A Helicopter Impeller Failure - Hydrogen Embrittlement – Fasteners

- Corrosion Overview

General Attack, Pitting, Intergranular Corrosion, Crevice Corrosion, Exfoliation and Microbiological Corrosion, Stress Corrosion, Corrosion Fatigue - Corrosion Control Methods

Designs to Minimize Corrosion, MIL-S-5002, MIL-F-7179, NAVAIR 01-1A-509, NDI, Materials Selection, Treatments, Coatings, Amlguard, Unicoat, Corrosion-X, ACF-50, Corrosion Block Grease, LPS… - Aging of Wiring

EWIS - NASA Aging Aircraft Efforts

- Engine Integrity

Turbine Disk Failure Modes, Bursting, Plasticity, Hi-Cycle & Low-Cycle Fatigue, Retirement for Cause, Short Crack Data ENSIP, Engine DTA, Case Study: United Airlines DC-10-10/CF6-6D Accident, Sioux City, Iowa, Fan Disk Investigations, Airline Inspections, The Role of FAA - Loads

Flight Loads Data Collection, Structures Technology, Ground and Handling loads, Truncation, Clipping, Omission - Aging General Aviation Aircraft

FAA / NAIR Cessna 402 Teardown, Best Practices Guide for Maintaining Aging General Aviation Aircraft - Nondestructive Inspection on Aging Fleet

D checks, Thermography, Probability of Detection Curves, X-ray,

Bolt-hole Eddy Current, Magnetic Particle, Ultrasonic, Penetrant - Nondestructive Testing of Aging Aircraft

- Pressure Test

Proof Tests Advantages and Disadvantages - Repair Techniques

Unique Problems in Multi-Site Damage, Composite Repair Methods, the Airworthiness Patch - Use of Damage Tolerance in Maintaining Airworthiness

- Cracks at Structural Holes

Fatigue Life Enhancement, Cold Working of Holes to Extend Airframe Life, Stress Intensity Factors, Cracks at Loaded Holes, Multiple Holes, Crack Growth Acceleration - Composites Fatigue & Damage Tolerance

Delaminations, Stiffness Losses, Fastener Hole Integrity, Impact Damage, Residual Strength Predictions, Moisture Ingression, Environmental Damage - Emerging NDI Technology For Aging Aircraft

Photogrammetry, Moire Motion Detection, Shearograph, New Holographic Techniques - Limit of Validity — LOV Concept