Course # 801C –

Fatigue, Fracture, Mechanics and Damage Tolerance of Aging and Modern Aircraft Structures

What you will accomplish and gain:

- GAIN solid understanding of the fundamentals of Metal Fatigue, Corrosion, and Ageing Composites

- RECEIVE knowledge and tools that’d enable them to operate an ageing fleet of aircraft and helicopters in an economical, yet safe fashion

- STUDY very practical case histories in a relaxed setting with interactive facilitation and be able to learn extremely valuable and real-life lessons

- UNDERSTAND technical expertise required to minimize the probability of a catastrophic accident

- PERFORM in-class fracture mechanics calculations with Sam’s individual attention

Who should take this training:

Managers / Engineers / Materials Scientists / Inspectors / DERs in:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From Industries including but not limited to:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Course # 801

Fatigue, Fracture Mechanics and Damage Tolerance of Aging and Modern Aircraft Structures

- Prologue

- Cost of Fracture

- The Danger of Metal Fatigue

- Early transportation failures from centuries past

- Bridges

- Trains

- Titanic and Liberty ships

- Wright Flyer, Comet, …

- F-111 crash

- Early transportation failures from centuries past

-

- What is a Failure? USAF-Navy-FAA-NASA Guidelines

- Structural Failure Modes

- Environmentally induced and/or time-dependent failure modes

- Creep, Fatigue, Corrosion, Wear, Fretting, Hydrogen Embrittlement

- Synergistic processes

- Corrosion fatigue, fretting fatigue, SCC, high temperature fatigue

- Why High Strength materials are weak in fatigue!

- Crack Initiation and Propagation

- Design Strategies to combat Metal Fatigue

- Safe Life

- Safety Factor fantasies

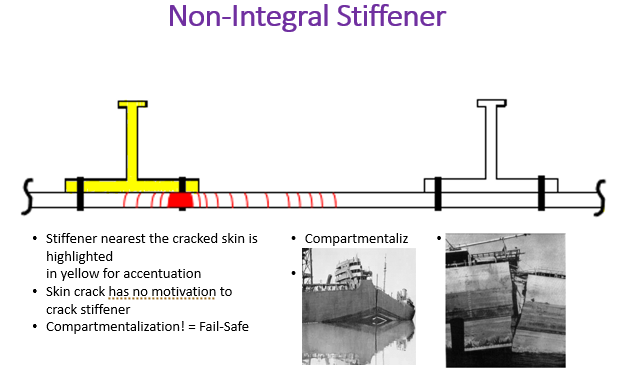

- Fail Safe

- 1. Crack Arrest

- 2. Multiple Load Path (Structural Redundancy)

- Design for inspectability

- Safe Life

- What is a Failure? USAF-Navy-FAA-NASA Guidelines

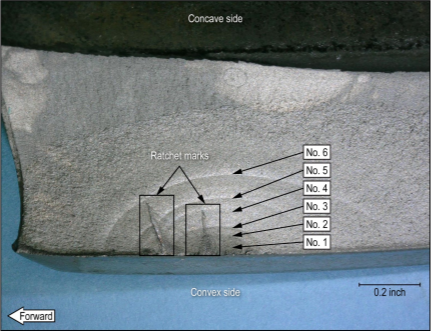

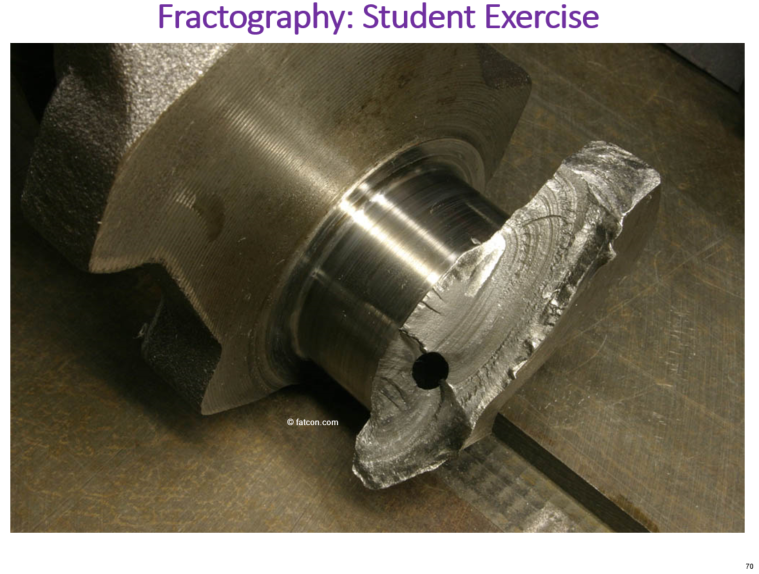

- Fractography

- What does a fatigue crack look like?

- Macro and Micro Aspects

- Striations and Beach Marks

- Quantitative and qualitative use

- Ratchet lines

- Marker cycles

- Guides on using Fractography

- Scanning Electron Microscope

- Use of fractography to perform failure analysis

- Stress Concentration Kt, Finishes

- Stress Concentrations

- Load Flow Lines (Streamlines): a useful analogy

- Surface finish

- Pitfalls in grinding

- Chrome-plating dangers, zinc and other platings

- Size effects

- Leonardo da Vinci

- Similitude or lack thereof

- Scatter, Reliability

- High Temperature Effects

- Stress Concentrations

- Fatigue Life Prediction

- Cycle parameters

- Range, amplitude, mean stress, R ratio

- S-N Curves

- Endurance Limit is largely a myth: Use Fatigue Strength

- Fatigue Strength

- Mean stress effects

- Constant Life Diagrams, Haigh Diagrams

- Low cycle fatigue

- Neuber’s Notch strain analysis

- Miner’s Myth

- Extremely limited applicability and lack of defensibility

- It is not a RULE

- Fracture Mechanics

- Griffith Criterion

- George Irwin, Naval Research Lab: Father of Fracture Mechanics

- Stress intensity factor SIF KI

- Beta factors

- Residual strength

- Fracture toughness

- Effect of thickness, orientation, impact, temperature

- Dynamic fracture toughness and crashworthiness

- Crack propagation

- Thresholds

- Inspection intervals

- Classroom problem-solving exercises

- NDE, detectable crack sizes

- Visual, eddy current, radiographic, ultrasonic, penetrant, magnetic particle

- Applicability, comparison

- POD (Probability of Detection)

- Reliability of Inspections

- Case Study: MD-88 uncontained engine failure

- Initial quality, EIFS equivalent initial flaw size

- Multiaxial stresses, Mixed mode cracking

- Short cracks

- Can be deadly

- Classroom tutorials in Fracture Mechanics

- Rigorous, parametric evaluations of various interconnected variables: fracture toughness, initial flaw size, inspection interval, fastener holes, corrosion effects, coldworking, shot-peening, da/dN, material properties C, m, …

- Damage Tolerance

- MIL-A-83444 -> MIL-A-87221 -> JSSG2006

- 1. Fail-safe structure

- Arrest of a rapidly running crack

- Safe partial failure of a load path

- Skin-stringer partnership

- Titanium crack stoppers

- 2. Slow crack growth structure

- Degree of inspectability

- Initial flaw assumptions

- 1. Fail-safe structure

- Retardation Models

- Willenborg

- Wheeler

- Closure

- Onera…

- Continuing damage

- ASIP, IATP

- Cycle parameters

- Environmentally Assisted Cracking

- Corrosion Fatigue

- Effect of frequency, waveform, hold-time, …

- Stress Corrosion

- KIscc

- SCC ratings for aircraft alloys

- Case study: SCC of a High Strength Steel Frame in a USNavy Fighter

- Fretting Fatigue

- How surface finish, similar materials in contact, slip amplitude, temperature, and environment affect Fretting Fatigue

- Contact fatigue

- Gear failures

- Aging aircraft issues

- Durability vs Damage Tolerance

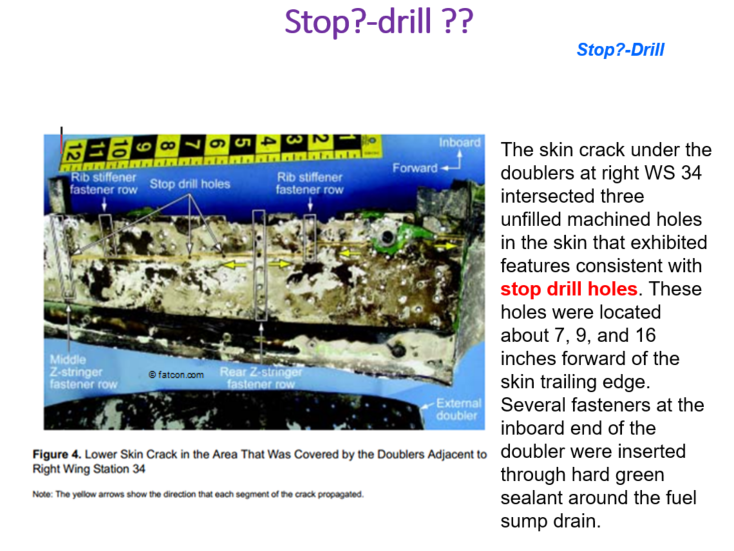

- Multi-Site Damage, Widespread Fatigue Damage

- The Aloha accident

- Continued airworthiness

- Supplemental inspection programs

- Limit of Validity (LOV)

- Corrosion Fatigue

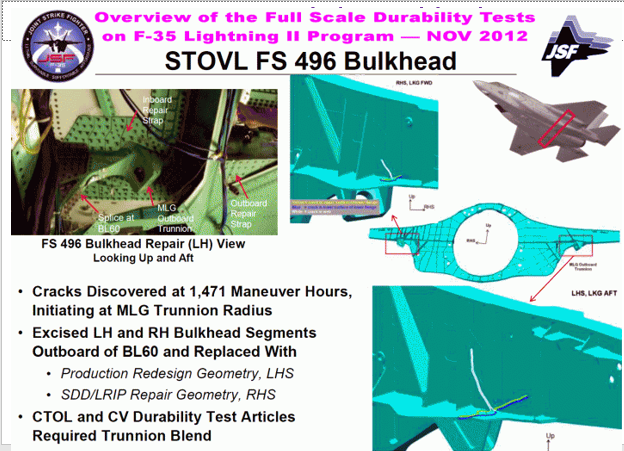

- Testing for Substantiation and Data accumulation

- Cycle Counting methods

- Rain flow method

- In-flight loads monitoring

- Testing

- Coupons, specimen, component, and Full-Scale

- Standardized Testing

- Coupon preparation, precracking guidelines

- E-399 KIc

- E-647 da/dN

- Service duplication Testing

- Environmental chambers

- Time compression issues in corrosion fatigue testing

- Load Spectrum Generation

- Canned Spectra

- TWIST, MINITWIST, TURBISTAN, HELIX, FELIX, …

- Sequence effects

- Truncation, clipping

- Canned Spectra

- Scatter, Reliability, Risk management

- Weibull Paper, Example problem

- Material Properties & Useful Data handouts and Sources

- S-N curves

- Crack initiation data

- da/dN crack growth data

- Fracture Toughness Kcs

- Data sources and handbooks

- Journals

- Cycle Counting methods

- Special Topics (Optional)

- Cracking in aircraft engine components

- ENSIP

- Sioux City DC-10 crash landing

- Thermo-mechanical Fatigue

- Creep Fatigue

- Thermal Fatigue

- Concorde

- Sonic fatigue (Acoustic Fatigue)

- Fatigue of composites

- Polymers

- ARALL, GLARE and other newer materials to fight fatigue

- Cracking in aircraft engine components

- Do’s and TABOOs

- Methods to improve fatigue resistance

- Clever use of favorable residual stresses

- Cold-working of holes

- Shot Peening

- Residual Stress control measures

- Bolts, Rivets, Springs, Bearings, Welds, …

- Failure Analysis: useful learning tool

- Care and handling of fractures

- Repair techniques

- Japan Air Lines 747 crash

- “stop”-drill?

- Helpful treatments and processes

- plating

- Hi-Tigue and other fatigue rated fasteners

- Guidelines based on experience

- Epilogue

- No highway

This syllabus is for guidance only; the syllabus may change retaining the current flavor.